Peeling Tools

Tools for bright steel companies

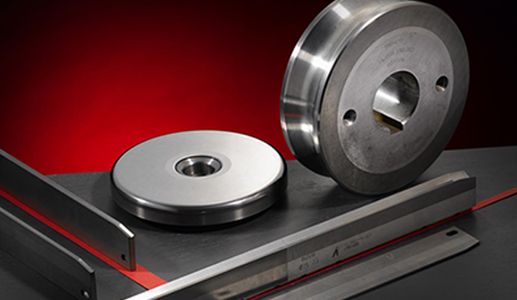

| peeling plates | polishing wheels, feed rollers |

| peeling heads, peeling holders and cassettes | end-machining: surface milling, facing, centering |

| rolls axles, roll holders, guiding parts | grinding tools, guiding tools for centerless grinding machines |

| wear parts of the feed unit and of the delivery unit |

Process

Tools for the peeling process

Peeling is a chip removal procedure to improve the surface value, the roundness and dimensions tolerance of cast, forged and rolled wire and merchant base. At about 1910 this procedure was developed and introduced in the market as an alternative to grinding or drawing. In the thirties and forties HSS peeling tools with flat arch cutters were produced, in the fifties the first tungsten carbide cutters appeared on the market. The high fracture rate was at this time the main problem for the tools use of tungsten carbide as cutting material in peeling machines.

At about 1970 Saar-Hartmetall und Werkzeuge GmbH started to develop tungsten carbide peeling tools. Up to the end of the eighties soldering tungsten carbide strips on the base steel body was the best fracture-proof solution for the production of these inserts. Solid tungsten carbide inserts concede gradually make their way up to the top only because of the improvements of the production processes of the primary material and the guide technique of the peeling machines.

Saar-Hartmetall und Werkzeuge GmbH has developed into a system supplier. We supply complete tool systems and application-optimized peeling inserts for peeling different material groups. In consultation with the customer, we optimise the process sequences, the peeling parameters and the tool designs (especially cutter head, holders, cassettes, inserts).

Tools for machining bar ends

Polishing and grinding

Advantages

- Our special knowledge in the field of peeling combined with a profound experience of the peeling operation in different applications is the ideal basis for customer adapted developments in the peeling process.

- A wide range of materials (various tungsten carbide grades, powder-metallurgically manufactured steels as well as our compound material) enables to solve problems of cutting, guiding and wear.

- Providing peeling inserts, cutterheads, holders, cassettes and tools for the guides in the peeling process all made in our company.

- Know-how of the processes upstream of the peeling process on the final product

- Know-how of the peeling process considering the cutting operation and the guiding of the material during the peeling process

- Know-how of the factors influencing the roundness, surface quality and structure of the peeled product

Service

- Tests at the peeling machine to optimize the geometry of the peeling inserts, particularly after buying new machines, transforming machines, changing the composition of the material, changing of the heat-treatment of the material or changes in the preceding production chain.

- Optimizing the tool systems in the case of changing demands of the user of the peeled (straightened / ground) products

- Training of the operators

- Optimizing the systems and tools for end-machining (chamfering, facing, centering)

- Optimizing the material side of wear intensive machine parts and guiding parts.