PM-Alloys

Powder Metallurgy

Wear- and temperature resistant components made of powdermetallurgical steels, Co-based alloys, super alloys and composite materials.

Compared with the conventional manufacture of materials based on the melting technology, the Powder Metallurgy provides special advantages:

- Alloys that cannot or can only be produced with enormous difficulties (for example higher carbide content).

- homogeneous material with no gravity segregation, solidification segregation, phase segregation and with isotropic properties.

- greater freedom of design of the components.

Industy sector and Products

| Steel production and Steel processing | Roll rings, guide rollers, cooling bed rollers |

| Food industry | Knives and cutters |

| Plastic industry | Tools for extrusion and injection molding |

| Automotive | and much more |

Large selection of materials as well as material combinations, single part production and small series.

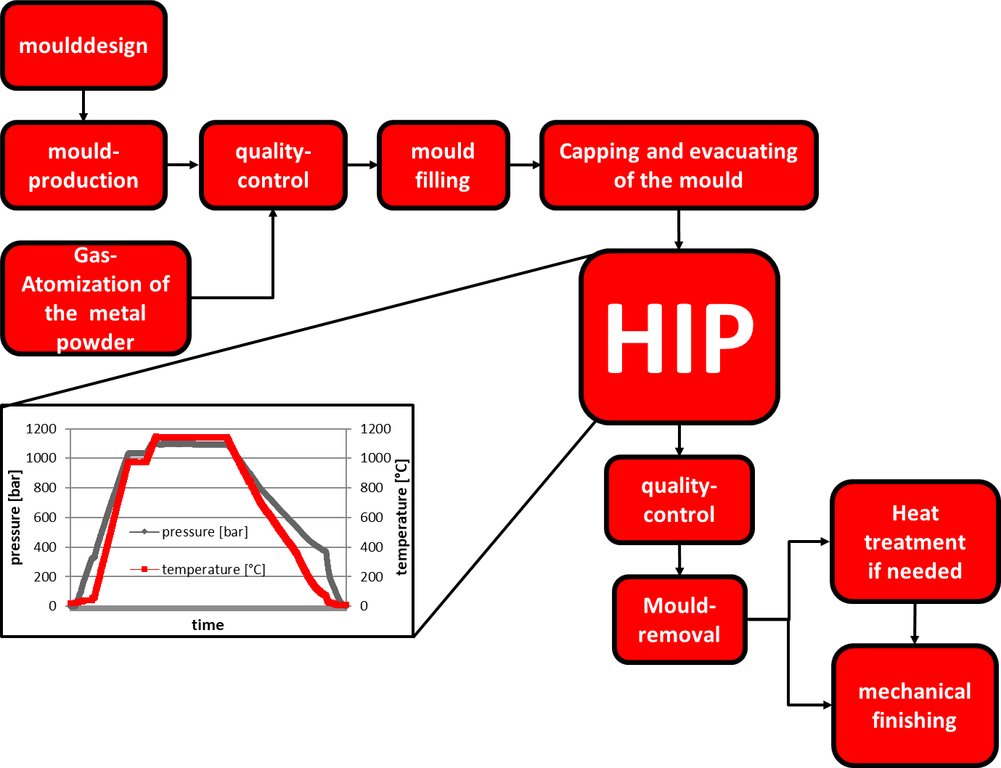

Process

- Use of gas-atomized powder in near-net shaped metal moulds.

- Hot Isostatic Pressing of the moulds at 1100°C – 1200°C and >1000 bar Bonding of the powders particles by means of the solid body diffusion.

- Mechanical removal of the moulds and further processing.

Tables of the different grades

[content in wt-%] – some examples

PM-Steels-Alloys (Saramet, SAM)

| Alloy | % C | % Cr | % Ni | % V | % Mo | % W | % Co | % Fe |

|---|---|---|---|---|---|---|---|---|

| Saramet (SAM) 9 | 1,85 | 5,3 | - | 9,0 | 1,3 | - | - | bal |

| Saramet (SAM) 10 | 2,45 | 5,3 | - | 9,8 | 1,3 | - | - | bal |

| Saramet (SAM) 15 | 1,57 | 4,0 | - | 5,0 | 0,5 | 12,5 | 5,0 | bal |

| Saramet (SAM) 23 | 1,3 | 4,0 | - | 3,1 | 4,9 | 6,0 | - | bal |

| Saramet (SAM) 26 | 2,7 | 26 | Nb:1,5 | 3,5 | 1,0 | - | - | bal |

| Saramet (SAM) 30 | 1,28 | 4,2 | - | 3,1 | 5,0 | 6,4 | 8,5 | bal |

| Saramet (SAM) 39 | 2,3 | 20,0 | Nb:2,0 | 4,5 | 1,0 | - | - | bal |

| Saramet (SAM) 41 | 0,95 | 18,0 | - | 0,2 | 1,1 | - | - | bal |

| Saramet (SAM) 53 | 2,45 | 4,2 | - | 8,0 | 3,1 | 4,2 | - | bal |

| Saramet (SAM) 60 | 2,3 | 4,2 | - | 6,5 | 7,0 | 6,5 | 10,5 | bal |

| Saramet (SAM) 316L | 0,02 | 16,5 | 10,5 | - | 2,1 | - | - | bal |

| Saramet (SAM) 4462 | 0,02 | 22,0 | 5,2 | - | 3,0 | - | - | bal |

Applications:

- High performance cold and hot working high speed steels (Forming-, cutting and pressing tools).

- Corrosion resistant tools; protection against intercrystalline corrosion.

PM-Superalloys (Saratherm, SAT)

| Alloy | % C | % Cr | % Mo | % Al | % Ti | % Co | % Ni |

|---|---|---|---|---|---|---|---|

| Saratherm (SAT) 2 | - | 15,00 | 5,00 | 4,00 | 3,50 | 18 | bal |

| Saratherm (SAT) 80 | - | 20,00 | - | 1,60 | 2,00 | 2 | bal |

| Saratherm (SAT) 90 | - | 20,00 | - | 1,50 | 2,50 | 18 | bal |

Applications:

Typical applications for high temperature resistant PM-Superalloys are

- high performance engine parts.

- high temperature resistant machine parts of the chemical and petrochemical industry.

- hot working tools in the diamond grinding disk- and glas industry, etc.

PM-Co-based alloys (Sarastel, SAS)

| Alloy | % C | % Cr | % W | % Mo | % Co |

|---|---|---|---|---|---|

| Sarastel (SAS) 1 | 2,50 | 32,00 | 13,00 | - | bal |

| Sarastel (SAS) 6 | 1,10 | 28,00 | 4,00 | - | bal |

| Sarastel (SAS) 12 | 1,50 | 30,00 | 9,00 | - | bal |

| Sarastel (SAS) 21 | 0,30 | 30,00 | - | 5,00 | bal |

Applications:

- Mining tools, cutting tools.

- Corrosion resisting high temperature engineering parts.

- Hot working tools.

Saracom

Tailored material properties in tool areas where these are required most:

- Hardmetal (cemented carbide) – Steel

- Co-based alloy (SAS) – Steel

- Superalloy - Steel

Advantages / Service

- Expert advice for the choice of the material.

- Common development of the applications with the customer.

- Production of small series possible.

- A great number of material combinations (reduction of cost) of steel and tungsten carbide/Saracom).