Wear / Formation Tools

Process

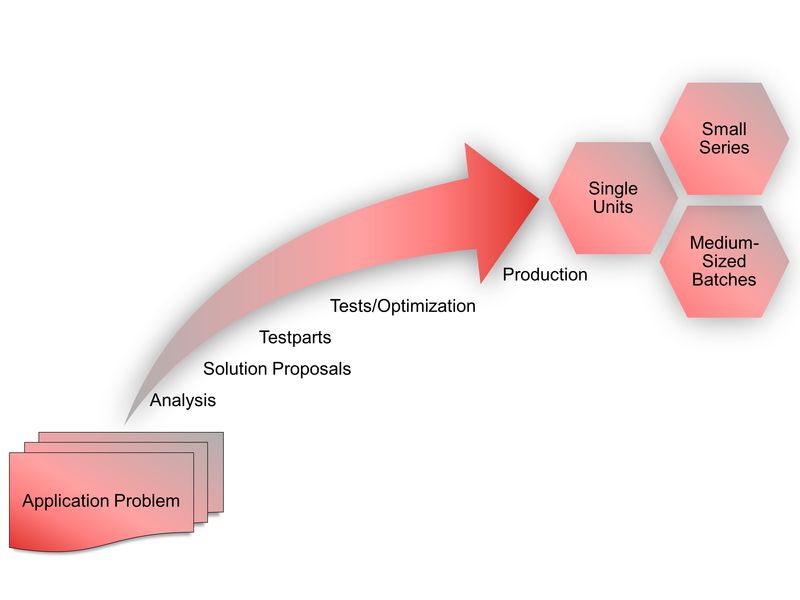

Advantages and service

We counsel actively at the spot to find solutions for your problems. Together we will be looking for application solutions.

We are able, to produce “one-unit” pieces. We are looking for applicable solutions by producing small- and medium sized numbers.

We have developed and made tungsten carbide for decades. Our portfolio contains numerous materials enabling us to offer individually tailored solutions for special problems of application.

Apart from components of or steel, we are also able to make composites of both material groups which are optimally adapted to a tailored to special applications.

Many tungsten carbide components and special solutions require high. We offer maintenance and reprocessing thus lengthening the life of the product.

Examples

- Highly wear resistant and corrosion-resistant screws, barrels and accessories of tungsten carbide for the processing of highly filled plastics, ceramics and material with halogen free flame retardant (UL-94-VO)

- Cutting blades and cutting knives made of corrosion-resistant tungsten carbide grades

- Dies and moulds of TC, PM steels and superalloys for the pressing and transforming technique

- Plates (corrosion resistant tungsten carbide, PM-steels and superalloys)

- Wear parts and special tools according to customer requests in tungsten carbide, PM-steels and superalloys