Powder Metallurgy

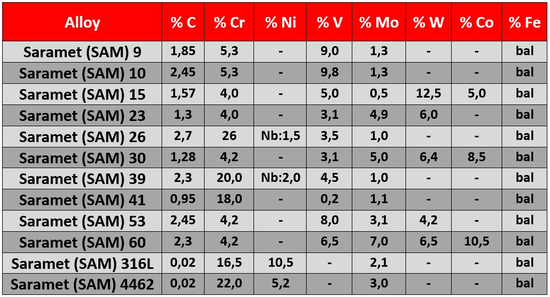

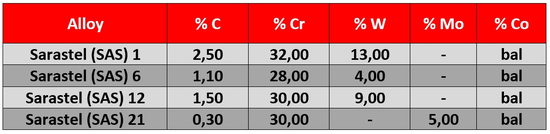

Wear- and temperature resistant components made of powdermetallurgical steels, Co-based alloys, super alloys and composite materials.

Compared with the conventional manufacture of materials based on the melting technology, the Powder Metallurgy provides special advantages:

- Alloys that cannot or can only be produced with enormous difficulties (for example higher carbide content)

- homogeneous material with no gravity segregation, solidification segregation, phase segregation and with isotropic properties

- greater freedom of design of the components

Industy sector and Products

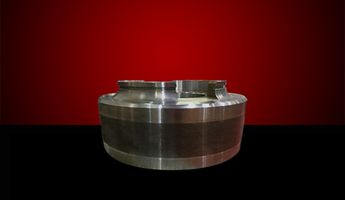

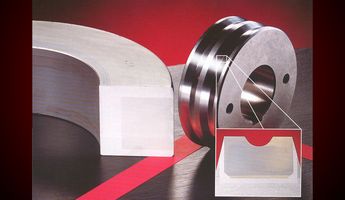

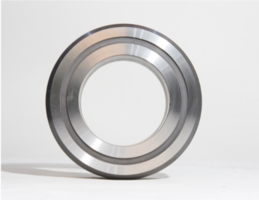

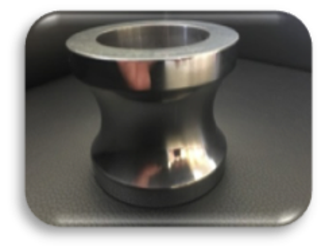

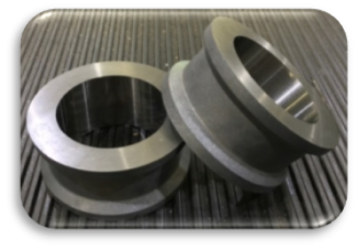

| Steel production and Steel processing | Roll rings, guide rollers, cooling bed rollers |

| Food industry | Knives and cutters |

| Plastic industry | Tools for extrusion and injection molding |

| Automotive | and much more |

Large selection of materials as well as material combinations, single part production and small series.