Tungsten carbide types for the hot transformation in roll mills

A long experience in the field of hot rolling enables Saar-Hartmetall und Werkzeuge GmbH to provide an extensive range of different materials with an optimal performance in all applications. The proposed cemented carbides (“SARAMANT”) are divided into the conventional WC-Co alloys and the corrosion resistant alloys with a mixed binder Co-Ni-Cr. Depending on the specific requirements in the rolling mill, cemented carbides with different grain sizes and different binder contents are used.

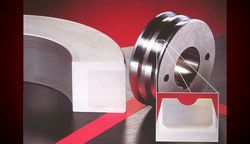

SARACOM Tungsten Carbide compounds roll rings

An important extension of the product range are the SARACOM roll rings, a combination of cemented carbide and steel. The clamping of these composite rings in the stand opens up a wide range of applications which would not be possible with the relatively brittle cemented carbide rings. For example it is possible to shrink these SARACOM roll rings on the shaft without any clearance between the shaft and the ring, which leads to an increased stiffness of the roll shaft and a higher rigidity of the system. The main fields of application of these composite roll rings are intermediate stands and blocks with a 3-ring layout as well as stretch reducing tube mills.

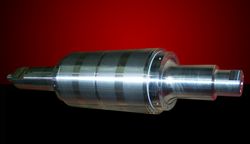

SARAMAX shaft systems

The mechanical SARAMAX clamping system equipped with SARACOM or SARAMET roll rings leads to a high wear resistant combiroll layout. Because of the long experience in this field of application and a continuous development of the clamping system it is possible to use the maximum width of the roll table. Our SARAMAX combirolls are provided with a maintenance- free clamping system which does not need to be retightened. Moreover, the roll shaft can be equipped several times with new roll rings.

Our SARAMAX combirolls are mainly used in the intermediate stands of bar and wire rod mills as well as in the finishing stands of bar mills.

PM steels for applications in rolling mills

The excellent microstructure of PM-steels compared to conventionally produced materials features a more homogeneous grain structure. Moreover, material properties such as tensile strength and toughness are increased because of the fine distribution of the spheroidal carbides. The high volume of carbides in the SARAMET PM-alloys in combination with a core hardness of 50 – 64 HRC is a guarantee for a high wear resistance and a long lifetime.

The SARASTEL cobalt base alloys and the SARATHERM superalloys enable the production of high temperature resistant tools, e.g. shear blades.

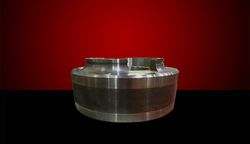

Applications for PM steels

The PM-steels are used for special applications. The use of SARAMET material for the slitting operation is only one example of many economical solutions.

Moreover they provide various possibilities of use in guiding rolls, twist rolls, loop lifters or cooling bed rolls. Normally SARAMET rolls are used when traditional tools do not achieve the desired performance.