Peeling is a chip removal procedure to improve the surface value, the roundness and dimensions tolerance of cast, forged and rolled wire and merchant base. At about 1910 this procedure was developed and introduced in the market as an alternative to grinding or drawing. In the thirties and forties HSS peeling tools with flat arch cutters were produced, in the fifties the first tungsten carbide cutters appeared on the market. The high fracture rate was at this time the main problem for the tools use of tungsten carbide as cutting material in peeling machines.

At about 1970 Saar-Hartmetall und Werkzeuge GmbH started to develop tungsten carbide peeling tools. Up to the end of the eighties soldering tungsten carbide strips on the base steel body was the best fracture-proof solution for the production of these inserts. Solid tungsten carbide inserts concede gradually make their way up to the top only because of the improvements of the production processes of the primary material and the guide technique of the peeling machines.

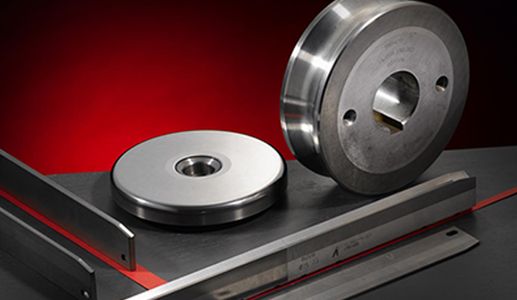

Saar-Hartmetall und Werkzeuge GmbH has developed into a system supplier. We supply complete tool systems and application-optimized peeling inserts for peeling different material groups. In consultation with the customer, we optimise the process sequences, the peeling parameters and the tool designs (especially cutter head, holders, cassettes, inserts).